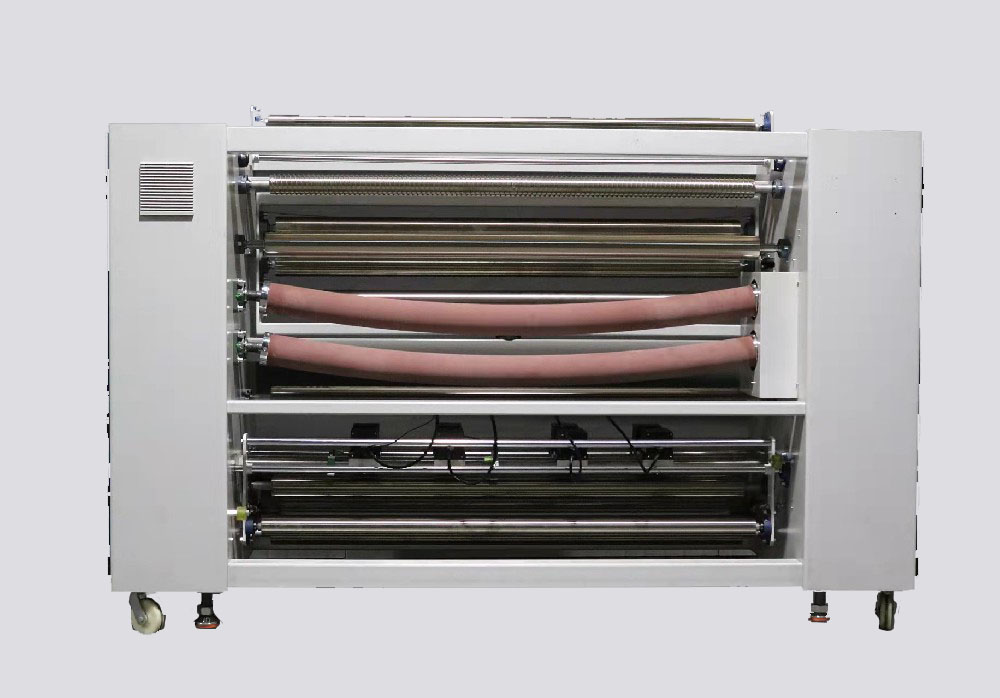

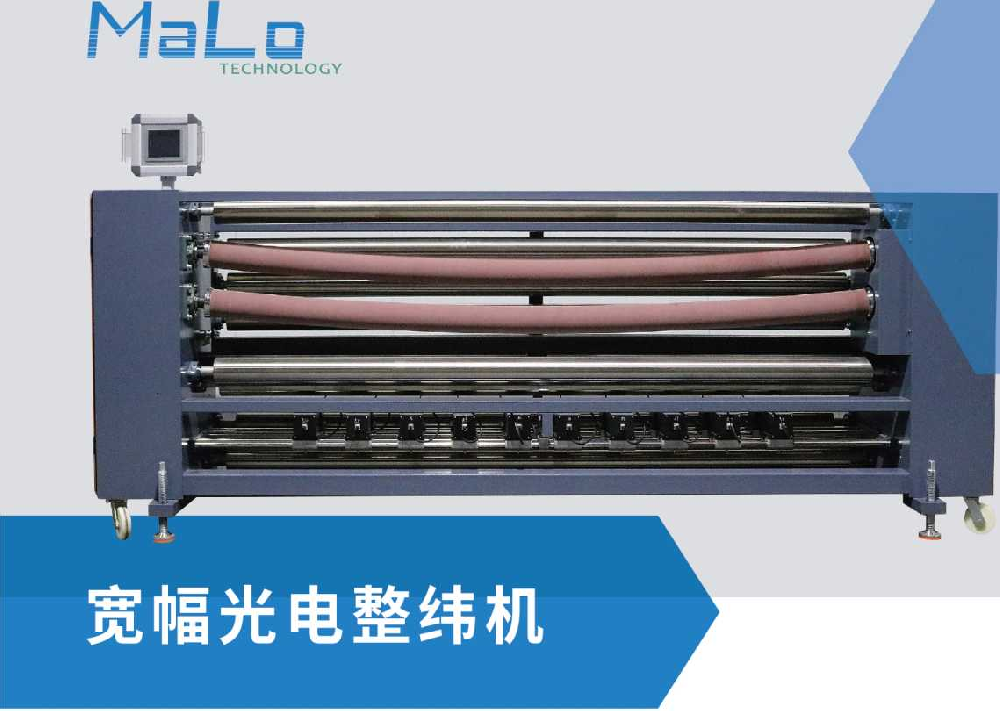

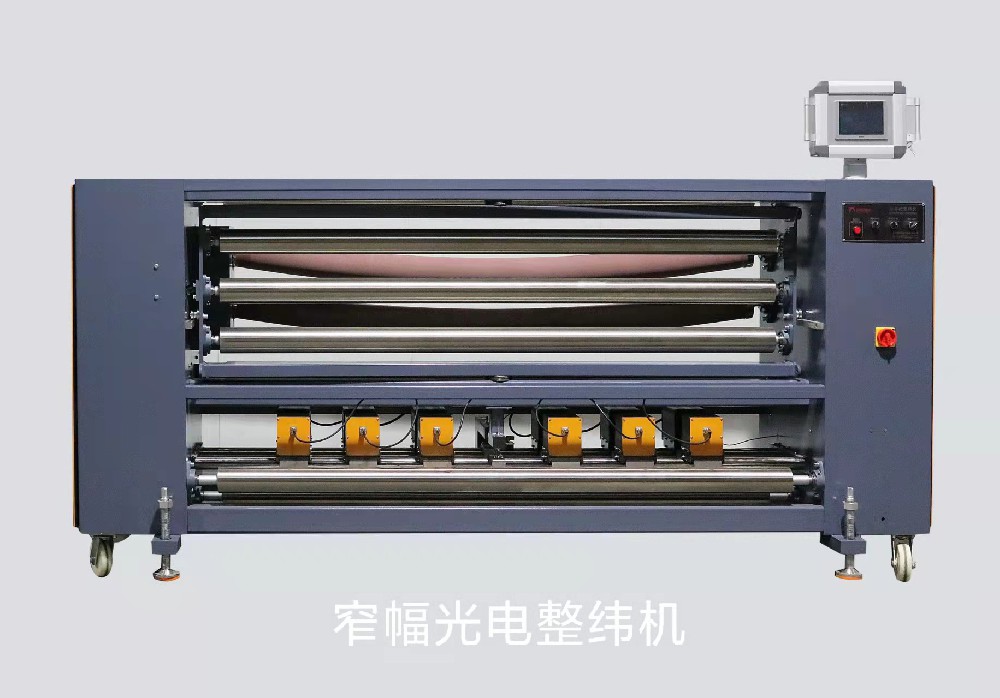

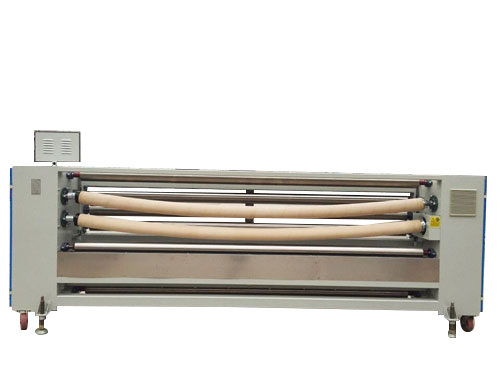

MLZW-IV-PZ型轉(zhuǎn)移印花型用整緯裝置

數(shù)碼印花整緯機(jī)

安裝位置 | 轉(zhuǎn)印印花機(jī) | ||

Installation location | Transfer printing machine | ||

適應(yīng)車速 | 全主動型2~60米/分 | ||

Speed | Active style:2~60m/min | ||

適應(yīng)范圍 | 機(jī)織織物 | 檢測緯密 | 10-350根/英寸 |

Suitable range | Woven fabrics | Weft density to be detected | 10-350picks/inch |

掘面長度 | 1400^3600 mm | 不銹鋼車?yán)ブ睆?/span> | 100mm/125mm |

| Length of roller su rface | 1400~3600mm | Diameter of guide roiler | 100mm/125mm |

矯緯掘 | 斜報(bào)三條、彎曲轅兩條或斜根三條,彎曲琨三條 | ||

Straightening rollers | Three sloping rollers and two bowing rollers or three sloping rollers anid three. | ||

矯緯范圍 | 緯斜<±30%織物寬,最大不超過750mm | ||

Straightening range | Bias weft< ±30% of fabric width and no wider than 750mm in max; | ||

彎掘傳動 | 主動型:彎輟主動傳輸,張力可調(diào) | ||

Driving of bowing roller | Active style:the bowing rollers are driven active ly,ten si on can adjust | ||

探測頭數(shù) | 4~10套探測器 | ||

Number of sensors | 4 ?lOsenors | ||

探頭位置 | 根據(jù)織物寬窄不同,探測器位置可以隨意移動(選購) | ||

| Probe position | According fabric width,the probe location free mobile(optional) | ||

信號采集方式 | (紅外線或直流燈)透射、紅外反射兩種工作模式 | ||

| Signal acquisition mode | Infrared transmission, infrared reflectance two different methods of work | ||

檢測角度 | MAX+15° | 檢測精度 | ±0.5° |

Detecting angle | MAX+15° | Detecting accuracy | ±0.5° |

斜、彎位置驅(qū)動 | 電腦控制交流變頻器實(shí)時(shí)驅(qū)動 | ||

Skew and bow position drive | Computer control ac motor-drives real-time drive | ||

客戶選配 Customer Selection | 1:活動放布架 ; 2:自動對邊裝置 3:恒張力控制系統(tǒng) 4:進(jìn)布對中機(jī) ; | 1: Movable Cloth Placing Rack 2: Automatic Edge Aligning Device 3: Constant Tension Control System 4: Cloth Feeding Centering Machine | |

人機(jī)界面顯示屏 | 7寸人機(jī)界面顯示屏 | ||

Man machine interface display | Man machine interface display | ||

| 電源、裝機(jī)容量 | 二相AC220V /三相AC380V, 50Hz.、2.25KVA/3.0KVA | ||

Power supply installation capacity | 2-phase AC220V/3-phase AC380V 50Hz、2.25KVA/3.0KVA | ||

重量 | 1200~2000kg | ||

Weight | 1200~2000kg | ||

- 上一篇:MLZW-IV-PZ型轉(zhuǎn)移印花型用整緯裝置

- 下一篇:沒有了!